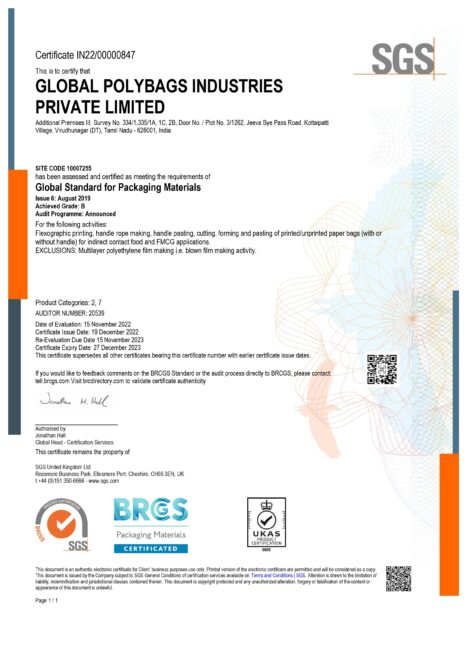

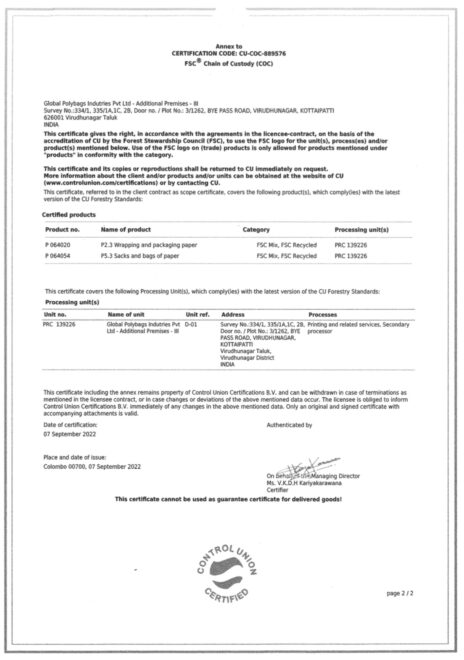

Reputably, our parent company ‘Global Polybags Industries Pvt Ltd’ is one of the BRCGS (Brand Reputation Compliance Global Standards) accredited paper bags manufacturing unit in India. Certified by the BRC (British Retail Consortium) authorized certification body, SGS United Kingdom Ltd. Only to be the sixth license holder of brand reputation compliant, food grade, safe & sustainable paper bags to be precise. Adding value to the above, we also hold the most coveted FSC (Forest Stewardship Council) Chain Of Custody certification. The FSC logo, considered the ‘Gold Standard‘ of forest certification by major environmental groups goes on to indicate that our paper bags are manufactured from responsibly harvested forests.

Perceiving a steady rise in environmentally conscious consumer behaviour, B2C brands have frantically endorsed paper bags in recent times. Aesthetically appealing quality of multi-colour printed paper bags aids in brand positioning and marketability of the product. Consequently, our 100% sustainable paper bags have been one of our high demand products.

Some of the features of our printed paper bags includes;

- 100% Recyclable

- Made of 40% recycled fibre

- Upto 6 colour printing

- Burst factor 28

- Block bottom bags with twisted handle

- Block bottom bags with flat handle

- SOS printed paper bags

- Square bottom bags

Customarily, by engaging the best-in-class GARANT TRIUMPH 5 QT, block bottom bag making machine unparalleled quality products are manufactured. Followed by LINAFLEX NL flexographic inline printing machine, exquisite finesse to our twisted handle and flat handle paper bags are achieved. Reputably introduced to the market by WINDMÖLLER & HÖLSCHER, a world market leader in printing, converting and extrusion machines for the packaging industry. Consistent development by GARANT and the use of SERVO technology has led to a reduction in set-up times by 50% on format changes in comparison to other block bottom bag machines.

The machine is popular across the world due to its high speed & ultra precision production lines combined with simplified operation which makes it ideal for the production of large-format block bottom bags and carrier bags.

The format range offered by TRIUMPH 5QT includes;

Bag Width: 180 – 460 mm

Bottom Width: 70 – 230 mm

Cut-off Length: 360 – 770 mm

Roll Width: up to 1370 mm

Roll Diameter: up to 1300 mm

LINAFLEX NL flexo inline printing presses endowed with perfectly coordinated coating and lamination systems could turn any package into an ambassador of the brand. As many as 6 color decks can be used as per the designer’s motive of choice and printed onto the packaging with superior print quality & vibrancy. Format range offered by LINAFLEX NL includes;

Printing Decks: up to 6

Printing Width: 700/900/1070/1200/1400 mm

Repeat Length: 250 – 850 mm

Machine Output Speed: 300 mts/min

Proficient manufacturing of our printed handle less paper bags also known as SOS bags is achieved through highline Jiangsu Fangbang ZD-FJ11+T, a fully automatic roll-fed paper bag machine with inline printing upto 4 colours. By seamlessly connecting flexo printing, tube forming, tube cutting and bottom forming, this machine efficiently conjoins printing with bag making. Thus, serving to be cost effective by down sizing equipment investment and labor. Varied range offered by this machine is as follows;

Paper Roll Width: 370 – 890 mm

Paper Thickness: 50 – 150 g/m2

Bag Body Width: 110 – 280 mm

Bag Bottom Size: 60 – 150 mm

Printing Repeat Length: 230 – 800 mm

Max Production Speed: 200 bags/min

High production rate at various size range has made this machine natural choice for application in food industry.

Yet another high performance machine from the Jiangsu Fangbang Machinery enterprise ZD-QFJ21S manufactures our square bottom paper bags without & with handles including twisted and flat. Machine implements steps including handle making, handle application, tube forming, tube cutting and bottom forming within a fully automated system.

Format range offered by ZD-QFJ21S includes;

Paper Roll Width: 630 – 1510 mm

Paper Thickness: 80 – 170 g/m2

Bag Body Width: 220 – 540 mm

Bag Bottom Size: 80 – 254 mm

Printing Width: 1460 mm

Printing Repeat Length: 230 – 800 mm

Handle Rope Height: 110 – 120 mm

Handle Rope Diameter: 4 – 6 mm

Handle Patch Length: 190.5 mm

Handle Patch Width: 40 – 50 mm

Max Production Speed: 120 – 150 bags/min